A whistle stop tour with Archimedes!

Accompanied by Dave Mann and his crew from Mannpower Consulting Ltd., we set off on our whistle stop tour beginning with a visit to the IFAT show in Munich and continuing on to visit some Archimedes Screw installations in Munich, Czech Republic and The Netherlands.

IFAT 2014 is the world´s leading exhibition of innovation solutions for environmental technology. Climate change, rising raw material prices, an increasing number of mega-cities and advancing industrialization in emerging countries boost the demand for products and services that address environmental and climate challenges. With growing pressures on European countries to reverse years of environmental damage and to find more integrated pollution control techniques, the potential is limitless.

The various exhibitions covering water, sewage, waste and raw materials management showcased the latest water technologies from around the world which identified strategies and applications that will aid the reversal of the damage done to our environment. A total of 3,081 exhibitors from 59 countries attended the show making this the biggest show for the water sector.

After the exhibition we set off to visit several of the Landy Archimedes Screw hydro installations and finished the tour with a visit to Landustrie the manufacturers of the Landy Archimedes screw based in The Netherlands.

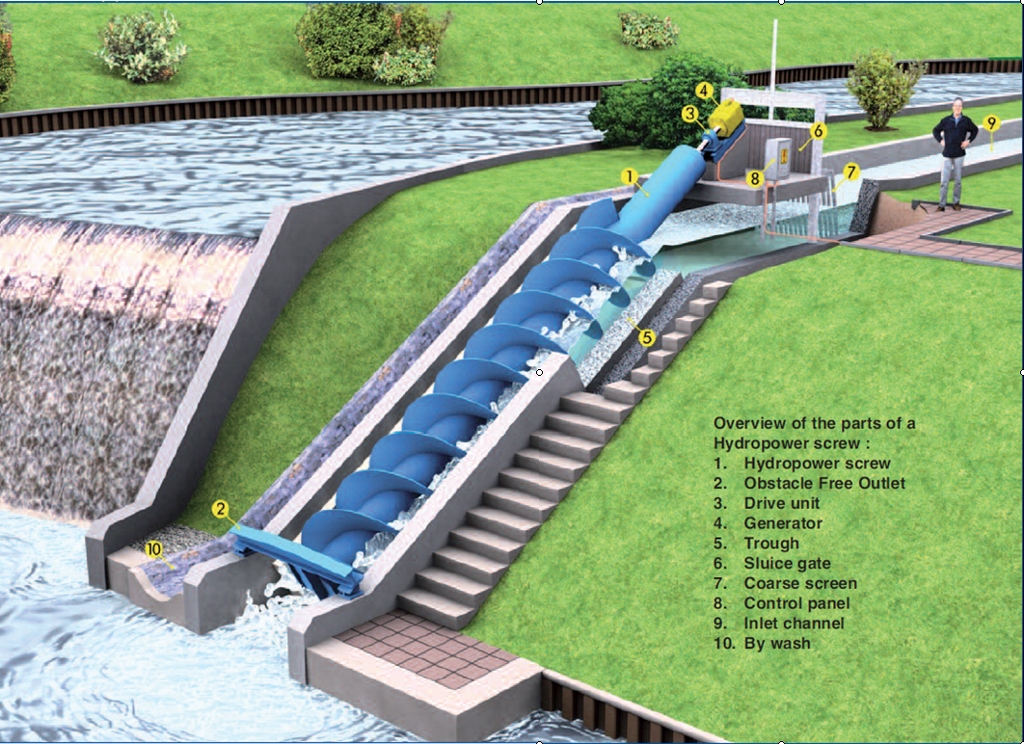

The Archimedean Screw has been used for pumping water for over 2000 years. Applying the principle in reverse, the same equipment now offers a new method for generating power from water, providing a fish friendly and highly efficient alternative to a conventional turbine. Each Archimedean Screw hydropower system is manufactured to be site-specific, with a choice of three designs depending on which is the most appropriate and cost-effective for each individual site.

In comparison with most turbines the Archimedean hydropower screw makes use of an open construction and a low rotational speed. This results in a natural flow and there is no pressure build up in the entire installation. Furthermore extensive testing shows that due to the size of water chambers and the fact that there is no pressure difference fish will pass through unharmed. The Landy hydropower screw makes use of a specially designed inlet and outlet that make the screw absolutely fish friendly. The water outlet is designed in such a way for the water (and fish) to smoothly exit the screw without splashing. This also reduces the noise that water creates.

The artwork displayed in the hall of Landustrie by Friesian artist Ymke Meester was commissioned to celebrate the 100th anniversary of Landustrie. It is a triptych depicting an impression of a fictitious industrial environment in which the screw pump and waterpower are central.

We design, install and commission hydropower schemes in both Ireland and the UK.